Strong operability, no specific inspection measuring tools

The characteristics of polishing technology mainly include strong operability, no specific inspection measuring tools, continuity, avoiding disorder, and regularity.

Polishing tools and equipment

Angular grinding machine: with a large contact area, suitable for large spaces, high efficiency, and easy to achieve flatness and smoothness.

Axial grinding machine: suitable for rounded corners and narrow spaces, easy to operate.

Angle grinding machine: including 90 degree angle grinding wheel and 120 degree angle grinding wheel, suitable for places where axial grinding wheel is not easy to operate.

Pen molding machine: suitable for small parts of small impellers.

Soft shaft grinding machine: suitable for places where small axial grinding machines cannot reach, the grinding wheel shaft can be bent arbitrarily.

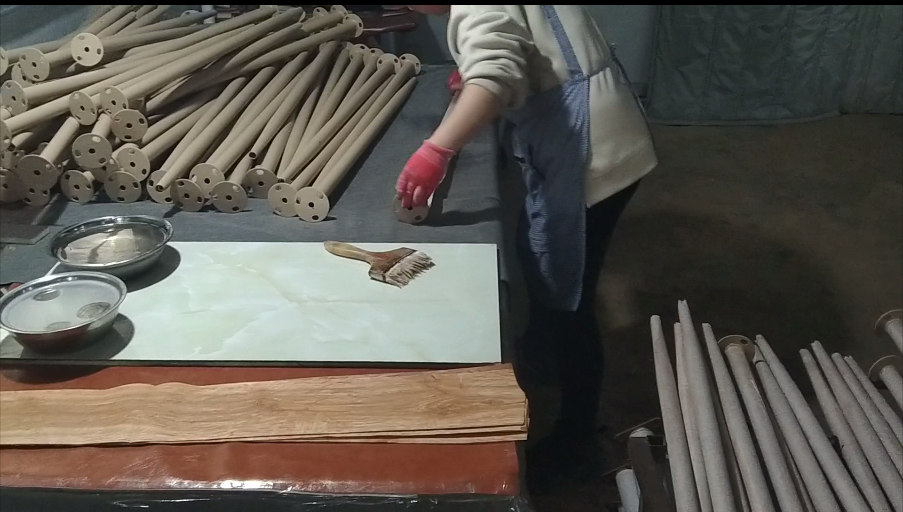

Polishing process and steps

Polishing process:

First, polish the R-corner where the blade intersects with the cover plate, and apply force towards the side of the cover plate.

Polish along the flow of the fluid, repair any defects with welding, and then proceed to the next process.

Vertical fluid flow direction, perpendicular to the previous polishing pattern.

Polishing steps:

Use a 24 # polishing pad for rough polishing.

Use 40 #, 60 #, and 80 # for semi precision polishing.

Use 100 # and 120 # for final polishing.

Finally, use rubber for polishing, and the pattern should be consistent with the previous polishing pattern.

Principles and precautions for polishing

Polishing principle: continuity, avoiding disorder, and having regularity.

Attention: Try to follow the principle of local first and then overall, and polish the blade thickness to be consistent as much as possible

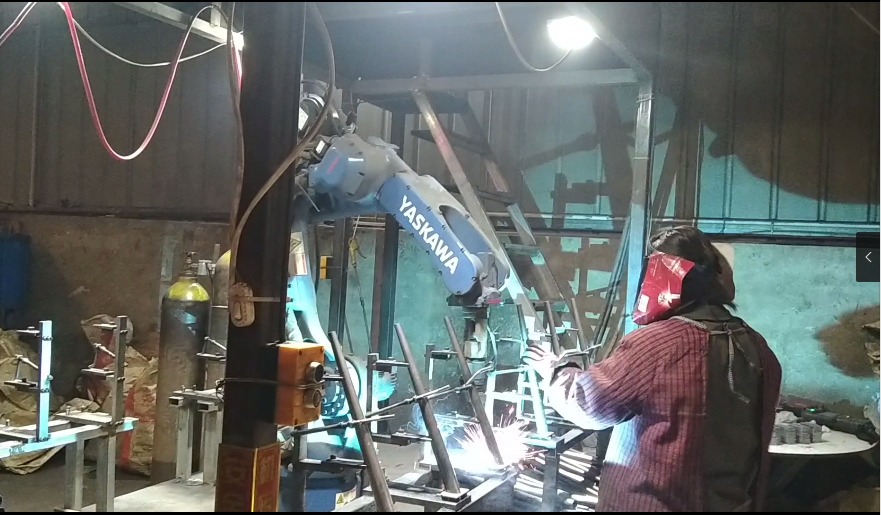

Main characteristics of welding process

Efficiency: The welding process is simple, the production efficiency is high, materials are saved, the cost is low, and it is conducive to product updates.

Flexibility: There are various welding methods that can weld almost all metal materials and some non-metal materials, with good connection performance.

Applicability: Welding technology is mainly used in the manufacturing of metal structures,

Diversity: Common welding methods include fusion welding (such as gas welding, arc welding, slag welding, etc.) and pressure welding (such as resistance welding, friction welding, cold pressure welding, etc.).

Diversity of positions: Welding positions include flat welding, horizontal welding, vertical welding, overhead welding, etc., suitable for different engineering requirements.

Advantages and disadvantages of welding process

Advantages:

Efficient: The welding process is simple, the production efficiency is high, and materials and costs are saved.

Flexible: Various welding methods can weld almost all metal materials and some non-metal materials, with good connection performance.

Strong applicability: widely used in fields such as building structures, ship hulls, vehicles, aerospace, electronic appliances, boilers, and pressure vessels.

Diversity: including various methods such as fusion welding and pressure welding to meet different engineering needs.

Special performance: Welding different materials together can give different parts or positions of the component different properties, meeting the requirements for use.

The main characteristics of spraying technology include the following aspects:

Wide applicability: The spraying process can be applied to various substrates, including metal, non-metal, etc., and the shape and size of the substrate are usually not limited.

Material diversity: The spraying process can use a variety of materials, such as metals, alloys, ceramics, composite materials, etc., which can endow the surface with various properties, such as corrosion resistance, wear resistance, high temperature resistance, thermal insulation, etc.

Small impact on the substrate: During the spraying process, the surface of the substrate is heated at a low temperature, usually between 200-250 ℃, and the overall temperature is about 70-80 ℃. Therefore, the deformation of the substrate is small and the material structure does not change.

Superior coating performance: Spray coating can have high hardness, such as macro hardness of spray coating containing hard phase up to 450HB, and spray welding layer up to 65HRC 1.

Environmental friendliness: The spray coating process is solvent-free, reducing environmental pollution and health risks for operators, while simplifying the coating process and improving production efficiency.

Efficiency: The spray coating process only requires a few steps such as spraying, curing, and cooling, greatly shortening the production cycle, and the utilization rate of powder coating is high, reaching over 95%.

Automated production: By configuring automatic painting machinery and recycling systems, automated production can be achieved, saving energy and resources.

High coating bonding strength: Some spraying processes such as plasma spraying have ultra-high temperature characteristics, high particle velocity, dense coating, and high bonding strength.

Specific applications and advantages and disadvantages of different spraying processes:

Flame spraying: suitable for general metal and non-metal substrates, with a wide range of materials, but little impact on the substrate and low bonding strength.

Silk flame spraying, powder flame spraying, supersonic flame spraying: high thermal efficiency and productivity, but low coating bonding strength.

Plasma spraying: suitable for spraying high melting point materials, with high particle velocity, dense coating, and high bonding strength.

Laser spraying and laser welding: suitable for surface treatment with high-precision requirements, but with higher equipment costs.

Arc spraying: Low cost, high productivity, but low coating bonding strength.

These characteristics make the spraying process have broad application prospects in various industrial applications.

The characteristics of cutting technology mainly include the following aspects:

Cutting quality: Laser cutting has a narrow and fine incision, smooth surface, small heat affected zone, high dimensional accuracy of up to ± 0.05mm, low surface roughness, and can even be used as the last process. The cutting seam of wire cutting processing can be as narrow as 0.005mm, with high material utilization rate, which can effectively save valuable materials.

Cutting efficiency: Laser cutting speed is fast, for example, cutting 2mm thick low-carbon steel plate at a speed of up to 600cm/min, and 5mm thick polypropylene resin plate at a speed of up to 1200cm/min. Although wire cutting processing has a slow speed, it has high processing accuracy and is suitable for processing low stiffness parts and small parts.

Scope of application: Laser cutting is suitable for various metal and non-metal materials, such as metal matrix composites, leather, wood, and fibers. Wire cutting processing is suitable for conductive or semi conductive materials such as copper, aluminum, steel, etc.

Environmental friendliness: Laser cutting is non-contact cutting, pollution-free, low noise, and small vibration, suitable for occasions with high environmental protection requirements. Wire cutting processing usually uses water-based working fluid, which can avoid fires and achieve continuous processing without human supervision day and night.

Equipment cost: Laser cutting equipment has a high cost, but the cutting quality is high, suitable for occasions with high-quality requirements. The cost of wire cutting processing equipment is relatively low, suitable for small and medium-sized production and processing of complex parts.

Easy to operate: Both laser cutting and wire cutting use CNC programming, which is easy to operate and suitable for automated production.

In summary, laser cutting and wire cutting each have their own advantages and disadvantages. Choosing the appropriate cutting process should be based on specific application requirements and cost considerations.

Slitting, die-cutting, and cutting are all ways of processing materials, but there are certain differences between them.

1. Slitting is the process of cutting large rolls of material to a certain width and length, and controlling the tension during the cutting process to maintain a certain level of tension to avoid affecting subsequent processing.

2. Die cutting is the process of cutting materials into the desired shape using a die cutting machine. Die cutting machine is a high-precision equipment that can cut materials into various shapes according to different molds, such as circles, squares, triangles, etc. Similar to making a mold, it’s just about shaping the material into the desired shape.

3. Cutting is the process of cutting large-sized fabrics or leather into small pieces or parts of the desired size or shape using a cutting machine.

Promoting production automation: With the development of technology, more and more assembly processes are being completed using automated equipment, which can improve production efficiency, reduce manual errors, and lower production costs.

The characteristics of quality inspection technology mainly include the following aspects:

Multiple types: There are numerous types of chemical products, each with its own specific inspection standards and requirements, which increases the complexity and diversity of quality inspection work.

Unstable properties: Many chemical products have unstable chemical properties, which require appropriate measures to be taken during the quality inspection process to ensure safety and stability.

High risk: Some chemical products have high risk, and strict safety and protective measures are required during the quality inspection process to prevent accidents from occurring.

The specific methods of quality inspection include:

Instrumental analysis method: using various instruments and equipment for detection, such as spectrometers, chromatographs, etc., suitable for precise analysis of components and structures.

Chemical analysis method: determines the composition and content of substances through chemical reactions, suitable for quantitative analysis of components.

Rapid analysis method: suitable for rapid detection of products in the production process to ensure production efficiency.

Standard analysis method: Conduct testing according to predetermined standards to ensure that product quality meets regulations.

The specific process of quality inspection includes:

Sampling: Obtain representative samples from the tested population to ensure their representativeness.

Preparation: Grind, sieve, mix, shrink and other treatments on the sample for subsequent testing.

Density determination: The relative density method, density bottle method, Wechsler balance method, and other methods are used for density determination.

Moisture determination: Moisture content is determined by methods such as drying, Karl Fischer method, azeotropic distillation, etc.

Viscosity measurement: Measuring the flow properties of fluids, including absolute viscosity and kinematic viscosity.

These methods and processes together constitute a complete system for quality inspection of chemical products, ensuring that product quality meets standards and requirements.

The characteristics of heat transfer printing technology mainly include the following aspects:

One time transfer molding of colored patterns: The heat transfer printing process can transfer colored patterns to the surface of the product in one go, without the need for color matching, reducing losses.

No ink residue, safe and non-toxic, environmentally friendly: During the heat transfer printing process, the ink layer blends seamlessly with the product surface without any ink residue, and the entire process is safe, non-toxic, and environmentally friendly.

Simple process and high efficiency: The heat transfer printing process is simple, with few steps and high efficiency. Even with simple equipment, realistic patterns can be printed.

The processed product is bright and beautiful, with bright colors and clear graphics and text: The surface of the product after heat transfer printing is bright and beautiful, with bright colors and clear graphics and text, greatly enhancing the added value of the product.

The application scope of heat transfer printing technology is very wide, including but not limited to printing of clothing, household textiles (such as curtains, sofas, tablecloths, umbrellas, shower curtains, bags) and other products. In addition, the heat transfer printing process also has the following disadvantages:

High requirements for substrates: Heat transfer printing can only be used for flat and high-temperature resistant substrates.

The texture of the pattern is relatively hard: Heat transfer printing patterns may feel a bit stiff when touched, and the breathability is relatively poor.

Color change: Clothing may change color after high-temperature pressing, especially white clothing may turn yellow, but after washing, the color will return to normal.

Post time: Nov-01-2024